Menu

Heat Press Machines

New Prisma A4 DTF Heat Press 8.3″X11.8″ Inch (40x50cm)

Sale

New Prisma A4 DTF Heat Press 8.3″X11.8″ Inch (40x50cm)

- Sale price

- $295

- Regular price

- $499

Auto-Open A3 Heat Press (13.78*16.54″) Prisma Palette by DTF STATION

Sale

Auto-Open A3 Heat Press (13.78*16.54″) Prisma Palette by DTF STATION

- Sale price

- $995

- Regular price

- $1,295

New Prisma Auto Clam Slider 110V 16X20" Inch DTF Heat-Press GS-105HS-Grey/Black With Auto Open Slider Feature And Pressure Sensor

Sale

New Prisma Auto Clam Slider 110V 16X20" Inch DTF Heat-Press GS-105HS-Grey/Black With Auto Open Slider Feature And Pressure Sensor

$19/Month Stahls Hotronix 15x15 Heat Press for T-Shirts Heat Transfer

Sale

$19/Month Stahls Hotronix 15x15 Heat Press for T-Shirts Heat Transfer

- Sale price

- $795

- Regular price

- $1,270

$59.99/Month Hotronix Fusion IQ T-Shirts Heat Press Transfer 16" x 20" - Touch Screen

$59.99/Month Hotronix Fusion IQ T-Shirts Heat Press Transfer 16" x 20" - Touch Screen

- Price

- $59.99

Prisma RAMLOCK Quick-Change Heat Press Platens For Prisma Swing Heat Press & Prisma Auto Heat Press

Prisma RAMLOCK Quick-Change Heat Press Platens For Prisma Swing Heat Press & Prisma Auto Heat Press

- Price

- From $82

DTF Station Prisma Dual DTF Printing Dual-Station Heat Press

DTF Station Prisma Dual DTF Printing Dual-Station Heat Press

Heat Press Machines for DTF Printing and T-Shirt Printing Equipment

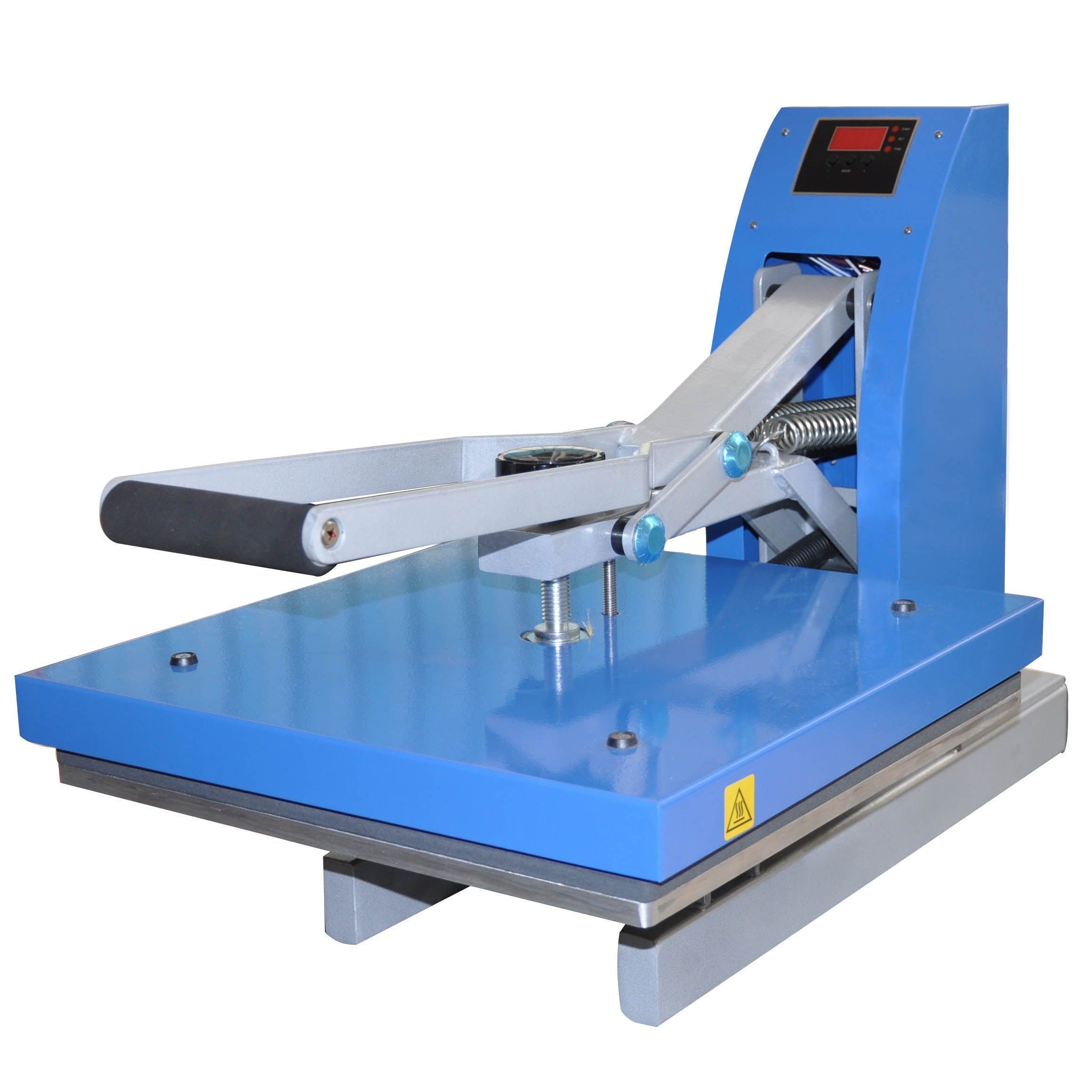

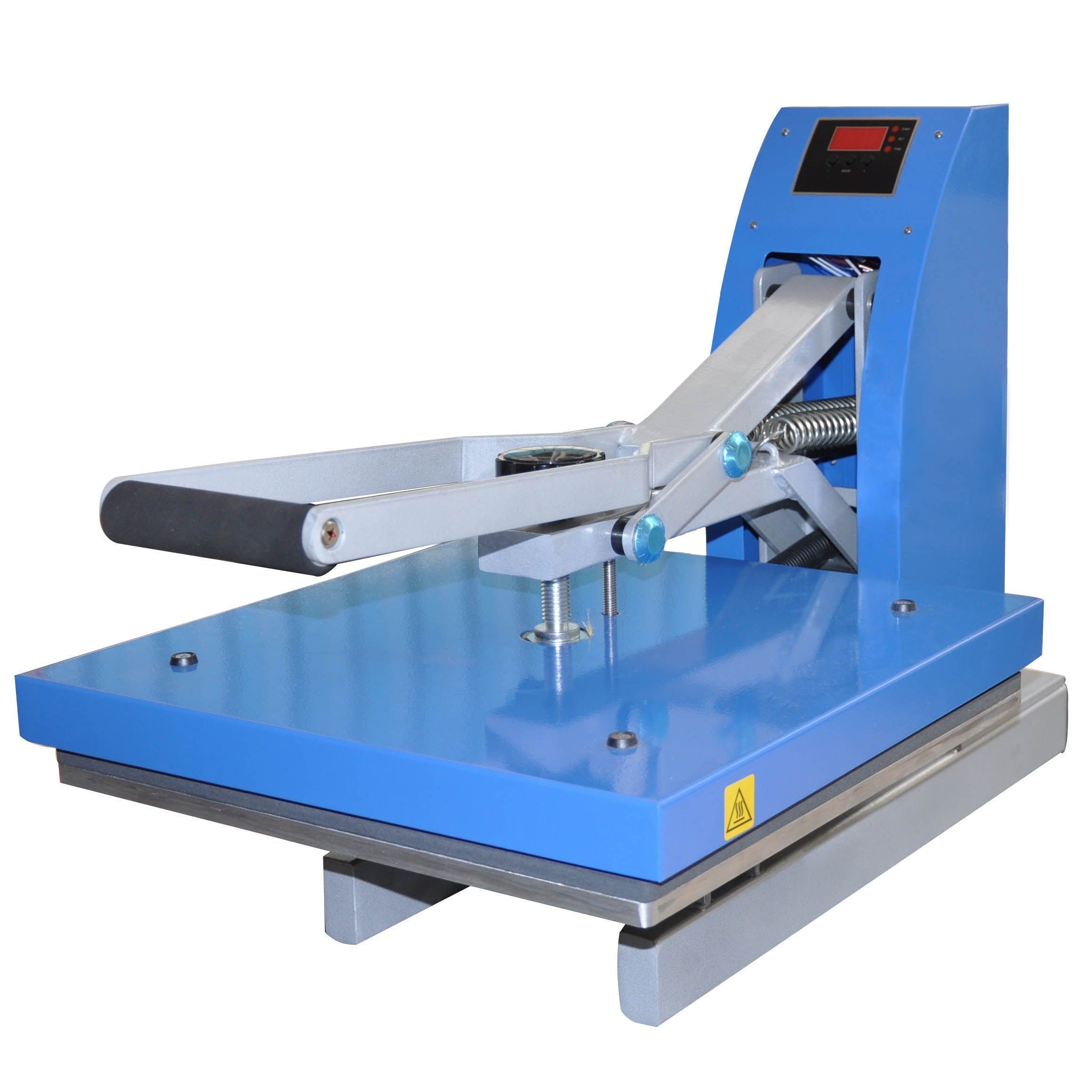

Heat press machines are vital for creating high-quality prints on a wide range of materials. They are used in direct-to-film (DTF) printing and t-shirt printing to transfer intricate designs, logos, and images onto garments and other products. Whether you're a newcomer to the printing industry or an experienced professional, choosing the right heat press is crucial for achieving consistent, durable results. In this collection, we explore the features and benefits of heat press machines tailored for DTF and t-shirt printing applications.

Overview of Heat Press Machines

Heat press machines are designed to apply heat and pressure to transfer printed designs onto materials. The process is highly effective for producing sharp, long-lasting prints, making heat press machines an essential piece of equipment for businesses offering custom t-shirt printing, apparel decoration, and more. These machines come in a variety of sizes and configurations, ensuring that there is a model for every business need, from small-scale operations to high-volume production.

Heat press machines are equipped with a platen that heats up to the desired temperature and presses down on the material. This process ensures that the printed design bonds securely with the substrate, whether it’s fabric, vinyl, or other materials. When selecting a heat press, it's important to consider several factors, such as platen size, temperature range, ease of use, and pressure adjustment.

Key Features to Look for in Heat Press Machines

When shopping for a heat press machine, there are several key features that can help improve efficiency, ease of use, and print quality. Here's a look at some of the most important aspects to consider:

1. Platen Size

The size of the platen is a critical consideration when choosing a heat press. Platen sizes range from small options for personal projects to larger formats suitable for mass production. For t-shirt printing, a medium-sized platen (around 15x15 inches) is often ideal, but larger sizes may be necessary for larger garments or multiple prints.

2. Temperature Control

Accurate temperature control is essential for ensuring that prints are transferred correctly. Heat press machines typically feature digital temperature controls, allowing you to set precise temperatures for different materials. This ensures that each print is applied with the optimal amount of heat, avoiding issues like fading or uneven transfers.

3. Pressure Adjustment

Even pressure is crucial for achieving consistent, high-quality prints. Heat press machines come with adjustable pressure settings, which ensure that the transfer process is uniform across the entire design. Machines with over-the-center pressure adjustment help distribute the pressure evenly across the platen, minimizing the risk of uneven transfers.

4. Ease of Use

Many heat press machines are designed for ease of use, making them suitable for beginners or those with limited experience. User-friendly features such as simple digital displays, one-touch operation, and intuitive controls can help streamline the printing process and increase productivity. A good heat press should require minimal setup and training.

5. Space-Saving Design

Some heat press machines come with compact designs that save space, making them ideal for small workshops or businesses with limited workspace. Clamshell-style heat presses, for example, are space-efficient and allow easy access to the platen, making it easier to handle materials and garments.

Benefits of Using Heat Press Machines for DTF and T-Shirt Printing

Heat press machines provide numerous benefits, especially when it comes to DTF printing and custom t-shirt production. Below are some of the advantages of investing in a high-quality heat press:

1. Consistency and Durability

Heat press machines deliver consistent results, ensuring that each print is of the same high quality. The combination of precise temperature control and pressure adjustment results in durable, long-lasting designs that won’t fade, crack, or peel over time.

2. Versatility

Heat press machines can handle a variety of materials, including t-shirts, hoodies, bags, mugs, and more. Whether you're working with cotton, polyester, or specialty fabrics, a heat press allows you to create custom designs on different substrates, making it a versatile tool for businesses offering diverse products.

3. Cost-Effective

Using a heat press machine can significantly reduce costs in the long run. Once the machine is set up, it is a cost-efficient way to produce high-quality prints in bulk. The equipment can also be used for small-run orders, giving businesses the flexibility to meet a wide range of customer demands.

4. Time Efficiency

Heat press machines streamline the printing process, reducing the time it takes to transfer designs onto products. With adjustable time and temperature settings, heat press machines allow users to fine-tune their settings to meet the specific needs of different materials, ensuring that each print is applied in a timely manner.

5. Low Maintenance

Most heat press machines require minimal maintenance. Regular cleaning and the occasional replacement of parts like heating elements can keep the machine running efficiently for years. Many models are also designed to be easily serviced, which helps minimize downtime in busy production environments.

Safety Guidelines for Using Heat Press Machines

While heat press machines are generally safe to use, it's important to follow safety guidelines to avoid accidents and ensure the longevity of the equipment. Here are some key safety practices to keep in mind:

- Proper Ventilation: Ensure that the heat press machine is used in a well-ventilated area to prevent overheating or the accumulation of harmful fumes, especially when working with certain materials.

- Temperature Monitoring: Always monitor the temperature settings to ensure that the machine is operating within the correct range. Overheating can damage both the machine and the materials being printed.

- Pressure Adjustment: Avoid over-pressing materials, as excessive pressure can cause damage to both the substrate and the print.

- Wear Protective Gear: Consider using heat-resistant gloves when handling hot materials to prevent burns or injury.

- Regular Maintenance: Perform regular maintenance on your heat press machine to keep it in top condition, ensuring safe and efficient operation.

Why Choose Absolute Toner for Your Heat Press Machine Needs?

When it comes to investing in high-quality heat press machines for DTF and t-shirt printing, Absolute Toner is your trusted source. We offer a wide selection of reliable and durable heat press machines designed to meet the needs of both small and large-scale operations. With a focus on precision, ease of use, and customer satisfaction, our products are tailored to help your business achieve the best results in custom printing.

By choosing Absolute Toner, you gain access to industry-leading equipment that delivers consistent, professional-quality prints every time. Whether you're just starting out or looking to upgrade your existing setup, we provide the tools you need to grow your business. Explore our collection of heat press machines today and take your DTF and t-shirt printing capabilities to the next level.

Need Help?

Chat, Call or Email Us

Our Printing Specialist team is always here to help!

905-326-2886

- Choosing a selection results in a full page refresh.