Menu

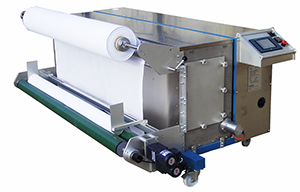

Brand New Mimaki TR300-1850S 72" Inch Steamer Ink Fixing and Color Fixing Machine Post Processing Workflow Solutions

Product Information

Brand New Mimaki TR300-1850S 72" Inch Steamer Ink Fixing and Color Fixing Machine Post Processing Workflow Solutions

The Mimaki TR300-1850S Steamer is a high-performance steaming machine designed to meet the exacting demands of the textile and fashion industries. Engineered for efficiency and precision, this state-of-the-art steamer is ideal for post-processing digitally printed textiles, ensuring vivid colors, sharp details, and durable prints on a variety of fabrics.

Key Features:

1. Generous Working Width:

- The TR300-1850S Steamer boasts a 1850mm working width, accommodating large rolls of fabric and enabling high-capacity processing. Whether you’re working with natural fibers like cotton and silk or synthetic blends, this steamer handles them all with ease, making it an excellent choice for diverse production needs.

2. Advanced Steam Distribution System:

- The steamer features an advanced steam distribution system that delivers consistent and uniform steam across the entire fabric surface. This ensures that colors are fully set, enhancing the longevity and vibrancy of the prints while preventing any color bleeding or fading.

3. Precise Temperature and Humidity Control:

- With precise temperature and humidity controls, the TR300-1850S allows you to tailor the steaming process to specific fabric types and printing methods. This level of customization ensures optimal results, whether you're working with reactive, acid, or disperse dyes.

4. Robust and Durable Construction:

- Built to withstand the rigors of continuous operation, the TR300-1850S features a sturdy construction with high-quality materials. Its durability ensures reliable performance over time, making it a valuable long-term investment for any textile production environment.

5. User-Friendly Interface:

- The steamer is equipped with an intuitive control panel that simplifies operation. Operators can easily adjust settings, monitor the steaming process, and make real-time adjustments as needed, ensuring smooth and efficient workflow.

6. Energy-Efficient Design:

- The TR300-1850S is designed with energy efficiency in mind, reducing operational costs while maintaining top-notch performance. Its efficient steaming process also minimizes fabric shrinkage and distortion, preserving the quality of the final product.

7. Easy Maintenance and Cleaning:

- Maintenance is straightforward with the TR300-1850S. The machine’s design allows for easy access to key components, making routine cleaning and upkeep hassle-free. This ensures the steamer operates at peak efficiency with minimal downtime.

The Mimaki TR300-1850S Steamer is ideal for businesses involved in fashion, home textiles, and custom fabric production. It is particularly suited for use in environments where high-quality, durable prints are essential, such as in the production of garments, upholstery, and decorative fabrics.

Main features

- Multifunctional roll-to-roll machine for both fabric preparation and finishing

- High level of efficiency and productivity, with low operating costs

- Very compact dryer

- The circulation of the pre-treatment liquid ensures the application in a constant state

- Small footprint, can be installed almost anywhere

The Mimaki TR300-1850S Steamer combines advanced technology with user-friendly features to deliver exceptional steaming performance. It is the perfect solution for textile manufacturers looking to enhance the quality and longevity of their digitally printed fabrics. With its robust design, precise controls, and energy-efficient operation, the TR300-1850S offers unmatched value in the textile processing industry.

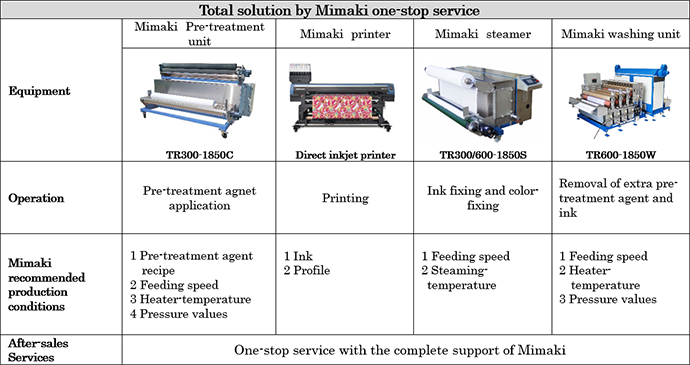

The current textile digital printing is requiring purchasing printers and pre- and post- processing devices from different manufacturers.

The production conditions depending on the fabric, ink and production place will be one of the important factors which control the finished quality (print penetration, image quality, color density, and dyeing property) and fixing up those conditions required much cost, time and knowledge.

The workflow of textile printing by inkjet printer

By providing pre-treatment unit, printer, steamer and washer as the completed system from Mimaki, it is possible to offer a total solution including equipment, recommended production conditions and know-how and easier for customers to proceed a new entry into digital printing business and in-house production.

As well, regarding direct sublimation printing, currently purchasing a pre-treated fabric was necessary but using the pre-treatment unit of "Rimslow Series" can realize the in-house work of pre-treatment process.

The unification of all the required equipment into Mimaki products will minimize the down time of machines for saving both time and money, as everything from initial consultation to production troubleshooting can be all handled by Mimaki.

Lineup / Specifications

TR300-1850S [Steamer]

![TR300-1850S [Steamer]](https://japan.mimaki.com/archives/052/201805/2f431255c1c0b145272c51e04437c17d.png)

Features

- A steaming machine that fixes the dye on the printed fabric and develops the color of the printed ink.

- Compact design that takes installation space into consideration, with the ability to unwind and rewind from the front

General Terms & Conditions

DTF Terms & Conditions

It is important that you carefully read and understand the DTF Printer Purchase – Terms & Conditions before completing your purchase.

All prices are listed in CAD and exclude applicable taxes. Unless otherwise stated, prices do not include shipping, setup, or training. Certain equipment may require mandatory training. Monthly lease payments may be subject to a required down payment. Please contact us for complete details.

Ask our Print Specialists for help · 905-326-2886

Pickup Location at 1300 Alness St. Unit 1A, Concord, ON

We Accept

Have a Question?

Copier Deals

$195/month GOLD KIT - GOLD/WHITE/SLV/CLR - Xerox C60 Production Printer with SERVER FIERY

Sale

$195/month GOLD KIT - GOLD/WHITE/SLV/CLR - Xerox C60 Production Printer with SERVER FIERY

- Sale price

- $195

- Regular price

- $998

ALL-INCLUSIVE CANON MAINTENANCE OFFICE COPIER PRINTER SCANNER 11x17, 12x18

Sale

ALL-INCLUSIVE CANON MAINTENANCE OFFICE COPIER PRINTER SCANNER 11x17, 12x18

- Sale price

- $795

- Regular price

- $3,500

$135/month Xerox® PrimeLink® C9065 Color Production Laser Printer - 2400x2400 DPI for Flyers and Business cards printing.

$135/month Xerox® PrimeLink® C9065 Color Production Laser Printer - 2400x2400 DPI for Flyers and Business cards printing.

- Sale price

- $6,950

- Regular price

- $35,000

Canon imageRUNNER ADVANCE C5560i III Color Multifunction Printer – High-Speed A3 Office Printer (Store Display Unit)

Canon imageRUNNER ADVANCE C5560i III Color Multifunction Printer – High-Speed A3 Office Printer (Store Display Unit)

- Price

- Free

$49/month Ricoh MP C4504EX Color Laser Multifunction Printer – Print, Copy, Scan, Fax | 45 ppm | 1200x1200 dpi*

$49/month Ricoh MP C4504EX Color Laser Multifunction Printer – Print, Copy, Scan, Fax | 45 ppm | 1200x1200 dpi*

- Sale price

- $2,499

- Regular price

- $4,599

Ricoh MP 3555 Black and White Laser Multifunction Printer – Copier, Scanner, Fax | Low Use*

Ricoh MP 3555 Black and White Laser Multifunction Printer – Copier, Scanner, Fax | Low Use*

- Sale price

- $1,950

- Regular price

- $2,689

$65/Month Ricoh IM3000 Color Multifunction Printer – Printer, Copier, Scanner | Only 20K Pages*

$65/Month Ricoh IM3000 Color Multifunction Printer – Printer, Copier, Scanner | Only 20K Pages*

- Sale price

- $2,950

- Regular price

- $5,200

$89/Month Canon imageRUNNER ADVANCE C5535i III Color Multifunction Printer | Copier | Scanner for Office – Lightly Used, Only 2K Pages*

$89/Month Canon imageRUNNER ADVANCE C5535i III Color Multifunction Printer | Copier | Scanner for Office – Lightly Used, Only 2K Pages*

- Sale price

- $89

- Regular price

- $139

$149/month Xerox Color C60 Pro Production Printer with Integrated Scanner & Copier*

$149/month Xerox Color C60 Pro Production Printer with Integrated Scanner & Copier*

- Sale price

- $6,950

- Regular price

- $8,999

$29/month Canon imagePROGRAF 24" Large Format Printer WITH STAND – NEW Store Display Model*

$29/month Canon imagePROGRAF 24" Large Format Printer WITH STAND – NEW Store Display Model*

- Sale price

- $995

- Regular price

- $1,599

$59/ month Ricoh IM C6000 – High-Performance Color Laser Multifunction Printer*

$59/ month Ricoh IM C6000 – High-Performance Color Laser Multifunction Printer*

- Sale price

- $2,950

- Regular price

- $3,890

$25/ month HP LaserJet Enterprise MFP M632h – High-Speed Monochrome Multifunction Printer*

$25/ month HP LaserJet Enterprise MFP M632h – High-Speed Monochrome Multifunction Printer*

- Sale price

- $1,000

- Regular price

- $2,500

Recommended for You

Recently Viewed

- Choosing a selection results in a full page refresh.

Order Support

Product Support

Corporate

Keep in Touch

Sign up for our newsletter and be the first to know about coupons and special promotions.

© 2026 Absolute Toner, and Printers. A Division of Precision Toner Corp.

Unless expressly stated, the toner, ink cartridges or all other supplies available for sale that are compatible with Samsung or any other Printer brands are not manufactured by Samsung, HP, Canon, Brother, Lexmark or any other brands or manufacturer.